China Brushless Dc Motor/Brushless Dc Electric Motor Manufacturers – 60-120W side brush motor professional used on the hand-push sweeper – INDEX

China Brushless Dc Motor/Brushless Dc Electric Motor Manufacturers – 60-120W side brush motor professional used on the hand-push sweeper – INDEX Detail:

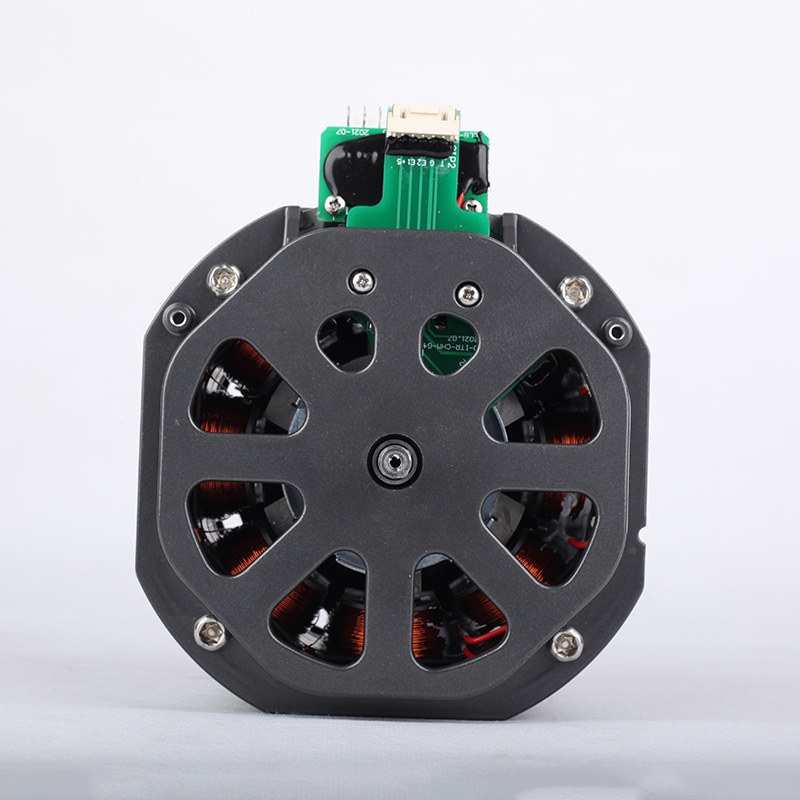

Product Details

The sweeper motor is a professional motor used for the main brush of the battery-type sweeper. The noise of this motor is lower than 60 decibels, and the life of the carbon brush is as high as 2000 hours (the life of the carbon brush of the general brush motor in the market can only reach 1000 hours). Our sweeper motor has been highly praised by well-known domestic and foreign cleaning equipment manufacturers, and has been exported to Europe and the United States.

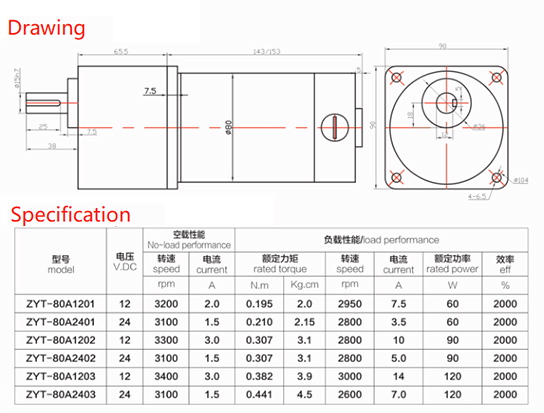

Product information

| Model | GM90D80A series |

| Name | Side brush motor of washing machine, AGV unmanned truck motor |

| Applications | Cleaning equipment, battery-type scrubbers, walk-behind scrubbers, sweepers, sweepers, etc. |

| Motor power | 60W-120W |

| Motor speed | can be customized |

| Warranty period | one year |

Design and structure characteristics of sweeper motor

The cooling method of the motor of the sweeper motor is divided into two categories: air cooling and liquid cooling. Air cooling is the simplest in structure, the cheapest in cost, and the most convenient in maintenance. Increase the ventilation volume, which will inevitably lead to an increase in ventilation loss, which reduces the efficiency of the motor. In addition, the temperature rise of the air-cooled stator and rotor windings is also higher. This affects the service life of the sweeper motor. The air-cooled cooling medium collects hydrogen from the air. Liquid-cooled media include water, oil, freon-based media used in evaporative cooling, and new non-polluting compound-based fluorocarbon media. The most commonly used hybrid motors are water-cooled and air-cooled.

In addition to the overall air cooling, the sweeper motor also has two commonly used cooling methods: water cooling and oil cooling. The method of recycling water cooling in the stator winding is quite common. Water is a good cooling medium, it has a large specific heat and thermal conductivity, cheap, non-toxic, non-combustible, and no explosion hazard. The cooling effect of water-cooled components is extremely significant, and the electromagnetic load that is allowed to withstand is much higher than that of air cooling, which improves the utilization rate of materials. However, the water joint and each sealing point are prone to short circuit, leakage and the danger of burning insulation due to the problem of water pressure leakage. Therefore, the water-cooled motor has very strict requirements on the sealing and corrosion resistance of the water channel, and antifreeze must be added in winter, otherwise it is easy to cause maintenance accidents. In the sweeper motor design, the water channel allows the cooling liquid to come into contact with every part of the inner surface of the motor. The flow direction design is to allow the coolant to better carry away the heat of the most prone to thermal failure parts, so special consideration is required for the design. In view of the fact that the water-cooling method still has certain shortcomings, some companies have independently designed an oil-cooling system. Due to the insulation of the cooling oil, it can penetrate into the interior of the motor rotor, stator winding, etc. for more complete heat exchange, and the cooling effect is better. It is good, but it is precisely because of this that the cooling oil needs to be strictly filtered, and the oil needs to be maintained and cleaned. It is necessary to avoid the sundries and metal chips being brought into the moving part of the motor to avoid the accident of the motor of the sweeper.

Product detail pictures:

Related Product Guide:

To create much more benefit for consumers is our company philosophy; customer growing is our working chase for China Brushless Dc Motor/Brushless Dc Electric Motor Manufacturers – 60-120W side brush motor professional used on the hand-push sweeper – INDEX , The product will supply to all over the world, such as: Iraq, Niger, Swansea, We have a dedicated and aggressive sales team, and many branches, catering to our customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.