Electric vehicles are mainly composed of three parts: motor drive system, battery system and vehicle control system. The motor drive system is the part that directly converts electrical energy into mechanical energy, which determines the performance indicators of electric vehicles. Therefore, the selection of the drive motor is particularly important.

In the environment of environmental protection, electric vehicles have also become a research hotspot in recent years. Electric vehicles can achieve zero or very low emissions in urban traffic, and have huge advantages in the field of environmental protection. All countries are working hard to develop electric vehicles. Electric vehicles are mainly composed of three parts: motor drive system, battery system and vehicle control system. The motor drive system is the part that directly converts electrical energy into mechanical energy, which determines the performance indicators of electric vehicles. Therefore, the selection of the drive motor is particularly important.

1. Requirements for electric vehicles for drive motors

At present, the evaluation of electric vehicle performance mainly considers the following three performance indicators:

(1) Maximum mileage (km): the maximum mileage of the electric vehicle after the battery is fully charged;

(2) Acceleration capability (s): the minimum time required for an electric vehicle to accelerate from a standstill to a certain speed;

(3) Maximum speed (km/h): the maximum speed that an electric vehicle can reach.

Motors designed for the driving characteristics of electric vehicles have special performance requirements compared to industrial motors:

(1) The electric vehicle drive motor usually requires high dynamic performance requirements for frequent start/stop, acceleration/deceleration, and torque control;

(2) In order to reduce the weight of the whole vehicle, the multi-speed transmission is usually cancelled, which requires that the motor can provide a higher torque at low speed or when climbing a slope, and usually can withstand 4-5 times the overload;

(3) The speed regulation range is required to be as large as possible, and at the same time, it is necessary to maintain a high operating efficiency within the entire speed regulation range;

(4) The motor is designed to have a high rated speed as much as possible, and at the same time, an aluminum alloy casing is used as much as possible. The high-speed motor is small in size, which is conducive to reducing the weight of electric vehicles;

(5) Electric vehicles should have optimal energy utilization and have the function of braking energy recovery. The energy recovered by regenerative braking should generally reach 10%-20% of the total energy;

(6) The working environment of the motor used in electric vehicles is more complex and harsh, requiring the motor to have good reliability and environmental adaptability, and at the same time to ensure that the cost of motor production cannot be too high.

2. Several commonly used drive motors

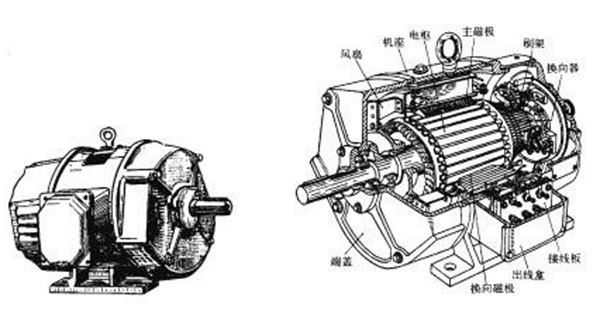

2.1 DC motor

In the early stage of the development of electric vehicles, most electric vehicles used DC motors as drive motors. This type of motor technology is relatively mature, with easy control methods and excellent speed regulation. It used to be the most widely used in the field of speed regulation motors. . However, due to the complex mechanical structure of the DC motor, such as: brushes and mechanical commutators, its instantaneous overload capacity and the further increase of the motor speed are limited, and in the case of long-term work, the mechanical structure of the motor will be Loss is generated and maintenance costs are increased. In addition, when the motor is running, the sparks from the brushes make the rotor heat up, waste energy, make it difficult to dissipate heat, and also cause high-frequency electromagnetic interference, which affects the performance of the vehicle. Due to the above shortcomings of DC motors, current electric vehicles have basically eliminated DC motors.

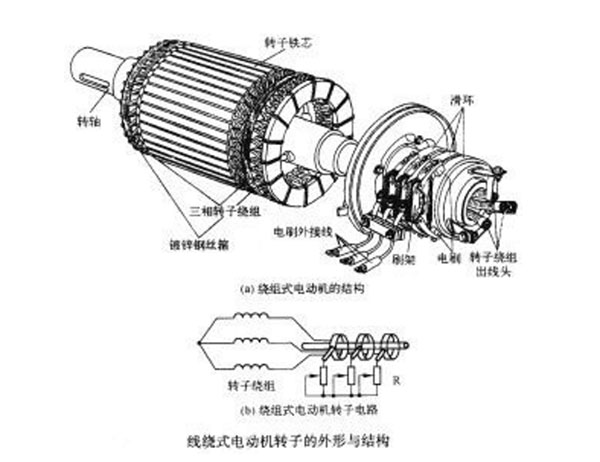

2.2 AC asynchronous motor

AC asynchronous motor is a type of motor that is widely used in the industry. It is characterized in that the stator and the rotor are laminated by silicon steel sheets. Both ends are packaged with aluminum covers. , reliable and durable operation, easy maintenance. Compared with the DC motor of the same power, the AC asynchronous motor is more efficient, and the mass is about one-half lighter. If the control method of vector control is adopted, the controllability and wider speed regulation range comparable to that of the DC motor can be obtained. Due to the advantages of high efficiency, high specific power, and suitability for high-speed operation, AC asynchronous motors are the most widely used motors in high-power electric vehicles. At present, AC asynchronous motors have been produced on a large scale, and there are various types of mature products to choose from. However, in the case of high-speed operation, the rotor of the motor is seriously heated, and the motor must be cooled during operation. At the same time, the drive and control system of the asynchronous motor is very complicated, and the cost of the motor body is also high. Compared with the permanent magnet motor and the switched reluctance For motors, the efficiency and power density of asynchronous motors are low, which is not conducive to improving the maximum mileage of electric vehicles.

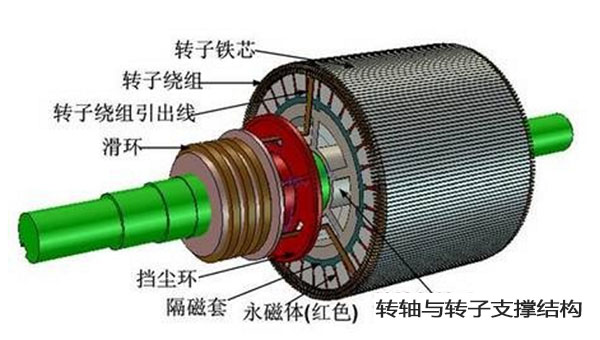

2.3 Permanent magnet motor

Permanent magnet motors can be divided into two types according to the different current waveforms of the stator windings, one is a brushless DC motor, which has a rectangular pulse wave current; the other is a permanent magnet synchronous motor, which has a sine wave current. The two types of motors are basically the same in structure and working principle. The rotors are permanent magnets, which reduces the loss caused by excitation. The stator is installed with windings to generate torque through alternating current, so cooling is relatively easy. Because this type of motor does not need to install brushes and mechanical commutation structure, no commutation sparks will be generated during operation, the operation is safe and reliable, the maintenance is convenient, and the energy utilization rate is high.

The control system of the permanent magnet motor is simpler than the control system of the AC asynchronous motor. However, due to the limitation of the permanent magnet material process, the power range of the permanent magnet motor is small, and the maximum power is generally only tens of millions, which is the biggest disadvantage of the permanent magnet motor. At the same time, the permanent magnet material on the rotor will have a phenomenon of magnetic decay under the conditions of high temperature, vibration and overcurrent, so under relatively complex working conditions, the permanent magnet motor is prone to damage. Moreover, the price of permanent magnet materials is high, so the cost of the entire motor and its control system is high.

2.4 Switched Reluctance Motor

As a new type of motor, the switched reluctance motor has the simplest structure compared to other types of drive motors. The stator and rotor are both double salient structures made of ordinary silicon steel sheets. There is no structure on the rotor. The stator is equipped with a simple concentrated winding, which has many advantages such as simple and solid structure, high reliability, light weight, low cost, high efficiency, low temperature rise, and easy maintenance. Moreover, it has the excellent characteristics of good controllability of the DC speed control system, and is suitable for harsh environments, and is very suitable for use as a drive motor for electric vehicles.

Considering that as electric vehicle drive motors, DC motors and permanent magnet motors have poor adaptability in structure and complex working environment, and are prone to mechanical and demagnetization failures, this paper focuses on the introduction of switched reluctance motors and AC asynchronous motors. Compared with the machine, it has obvious advantages in the following aspects.

2.4.1 The structure of the motor body

The structure of the switched reluctance motor is simpler than that of the squirrel-cage induction motor. Its outstanding advantage is that there is no winding on the rotor, and it is only made of ordinary silicon steel sheets. Most of the loss of the entire motor is concentrated on the stator winding, which makes the motor simple to manufacture, has good insulation, is easy to cool, and has excellent heat dissipation characteristics. This motor structure can reduce the size and weight of the motor, and can be obtained with a small volume. larger output power. Due to the good mechanical elasticity of the motor rotor, switched reluctance motors can be used for ultra-high-speed operation.

2.4.2 Motor drive circuit

The phase current of the switched reluctance motor drive system is unidirectional and has nothing to do with the torque direction, and only one main switching device can be used to meet the four-quadrant operation state of the motor. The power converter circuit is directly connected in series with the excitation winding of the motor, and each phase circuit supplies power independently. Even if a certain phase winding or the controller of the motor fails, it only needs to stop the operation of the phase without causing a greater impact. Therefore, both the motor body and the power converter are very safe and reliable, so they are more suitable for use in harsh environments than asynchronous machines.

2.4.3 Performance aspects of motor system

Switched reluctance motors have many control parameters, and it is easy to meet the requirements of four-quadrant operation of electric vehicles through appropriate control strategies and system design, and can maintain excellent braking ability in high-speed operation areas. Switched reluctance motors not only have high efficiency, but also maintain high efficiency over a wide range of speed regulation, which is unmatched by other types of motor drive systems. This performance is very suitable for the operation of electric vehicles, and is very beneficial to improve the cruising range of electric vehicles.

3. Conclusion

The focus of this paper is to put forward the advantages of switched reluctance motor as a drive motor for electric vehicles by comparing various commonly used drive motor speed control systems, which is a research hotspot in the development of electric vehicles. For this type of special motor, there is still a lot of room for development in practical applications. Researchers need to make more efforts to carry out theoretical research, and at the same time, it is necessary to combine the needs of the market to promote the application of this type of motor in practice.

Post time: Mar-24-2022