Can the motor core also be 3D printed? New progress in the study of motor magnetic cores

The magnetic core is a sheet-like magnetic material with high magnetic permeability. They are commonly used for magnetic field guidance in various electrical systems and machines, including electromagnets, transformers, motors, generators, inductors and other magnetic components.

So far, the 3D printing of magnetic cores has been a challenge due to the difficulty in maintaining core efficiency. But a research team has now come up with a comprehensive laser-based additive manufacturing workflow that they say can produce products that are magnetically superior to soft-magnetic composites.

© 3D Science Valley White Paper

3D printing electromagnetic materials

Additive manufacturing of metals with electromagnetic properties is an emerging field of research. Some motor R&D teams are developing and integrating their own 3D printed components and applying them to the system, and design freedom is one of the keys to innovation.

For example, 3D printing functional complex parts with magnetic and electrical properties could pave the way for custom embedded motors, actuators, circuits and gearboxes. Such machines can be produced in digital manufacturing facilities with less assembly and post-processing, etc., since many parts are 3D printed. But for various reasons, the vision of 3D printing large and complex motor components has not materialized. Mainly because there are certain challenging requirements on the device side, such as small air gaps for increased power density, not to mention the issue of multi-material components. So far, research has focused on more “basic” components, such as 3D-printed soft-magnetic rotors, copper coils, and alumina heat conductors. Of course, soft magnetic cores are also one of the key points, but the most important obstacle to be solved in the 3D printing process is how to minimize the core loss.

▲ Tallinn University of Technology

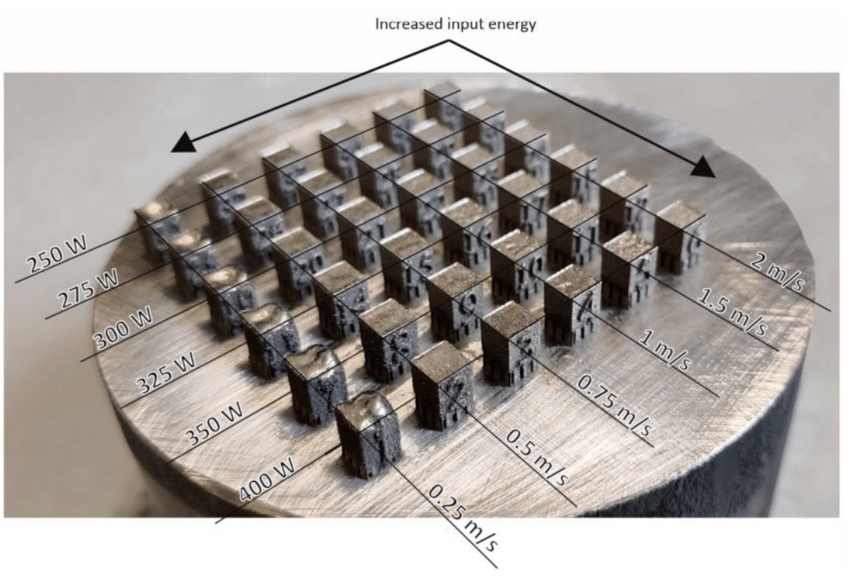

Above is a set of 3D printed sample cubes showing the effect of laser power and printing speed on the structure of the magnetic core.

Optimized 3D printing workflow

To demonstrate the optimized 3D printed magnetic core workflow, the researchers determined the optimal process parameters for the application, including laser power, scan speed, hatch spacing, and layer thickness. And the effect of annealing parameters was studied to achieve minimum DC losses, quasi-static, hysteresis losses and highest permeability. The optimum annealing temperature was determined to be 1200°C, the highest relative density was 99.86%, the lowest surface roughness was 0.041mm, the lowest hysteresis loss was 0.8W/kg, and the ultimate yield strength was 420MPa.

▲ The effect of energy input on the surface roughness of the 3D printed magnetic core

Finally, the researchers confirmed that laser-based metal additive manufacturing is a feasible method for 3D printing motor magnetic core materials. In future research work, the researchers intend to characterize the part’s microstructure to understand grain size and grain orientation, and their effect on permeability and strength. The researchers will also further investigate ways to optimize the 3D printed core geometry to improve performance.

Post time:

Aug-03-2022