Among them, the Mach electric drive part has the following characteristics:

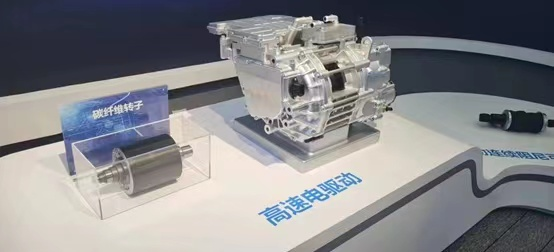

- Motor with carbon fiber coated rotor technology, the speed can reach 30,000 rpm;

- oil cooling;

- Flat wire stator with 1 slot and 8 wires;

- Self-developed SiC controller;

- The maximum efficiency of the system can reach 94.5%.

Compared with other technologies, the carbon fiber-coated rotor and the maximum speed of 30,000 rpm have become the most distinctive highlights of this electric drive.

High RPM and Low Cost Intrinsically Linke

Yes, cost-driven results!

The following is an analysis of the relationship between the motor speed and the cost of the motor at the theoretical and simulation levels.

The new energy pure electric drive system generally includes three parts, the motor, the motor controller and the gearbox. The motor controller is the input end of electric energy, the gearbox is the output end of mechanical energy, and the motor is the conversion unit of electric energy and mechanical energy. Its working method is that the controller inputs electric energy (current * voltage) into the motor. Through the interaction of electric energy and magnetic energy inside the motor, it outputs mechanical energy (speed*torque) to the gearbox. The gear box drives the vehicle by adjusting the speed and torque output by the motor through the gear reduction ratio.

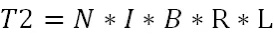

By analyzing the motor torque formula, it can be seen that the motor output torque T2 is positively correlated with the motor volume.

N is the number of turns of the stator, I is the input current of the stator, B is the air flux density, R is the radius of the rotor core, and L is the length of the motor core.

In the case of ensuring the number of turns of the motor, the input current of the controller, and the flux density of the motor air gap, if the demand for the output torque T2 of the motor is reduced, the length or diameter of the iron core can be reduced.

The change of the length of the motor core does not involve the change of the stamping die of the stator and rotor, and the change is relatively simple, so the usual operation is to determine the diameter of the core and reduce the length of the core.

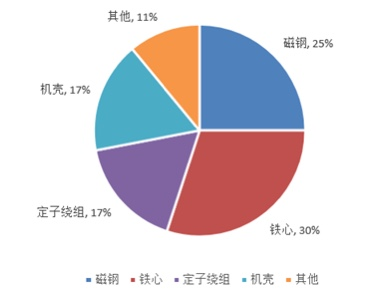

As the length of the iron core decreases, the amount of electromagnetic materials (iron core, magnetic steel, motor winding) of the motor is reduced. Electromagnetic materials account for a relatively large proportion of the motor cost, accounting for about 72%. If the torque can be reduced, the motor cost will be significantly reduced.

Motor cost composition

Because new energy vehicles have a fixed demand for wheel end torque, if the output torque of the motor is to be reduced, the speed ratio of the gearbox must be increased to ensure the wheel end torque of the vehicle.

n1=n2/r

T1=T2×r

n1 is the speed of the wheel end, n2 is the speed of the motor, T1 is the torque of the wheel end, T2 is the torque of the motor, and r is the reduction ratio.

And because new energy vehicles still have the requirement of maximum speed, the maximum speed of the vehicle will also decrease after the speed ratio of the gearbox is increased, which is unacceptable, so this requires that the motor speed must be increased.

To sum up, after the motor reduces torque and speeds up, with a reasonable speed ratio, it can reduce the cost of the motor while ensuring the power demand of the vehicle.

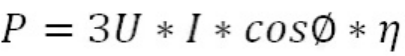

Influence of de-torsion speed-up on other properties01After reducing the torque and speeding up, the length of the motor core decreases, will it affect the power? Let’s look at the power formula.

It can be seen from the formula that there are no parameters related to the size of the motor in the formula of the motor output power, so the change of the length of the motor core has little effect on the power.

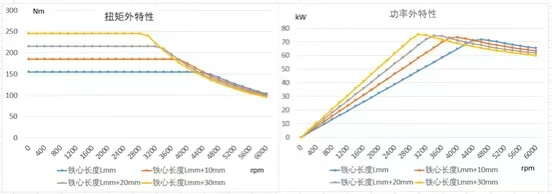

The following is the simulation result of the external characteristics of a certain motor. Compared with the external characteristic curve, the length of the iron core is reduced, the output torque of the motor becomes smaller, but the maximum output power does not change much, which also confirms the above theoretical derivation.

Post time: Apr-19-2023