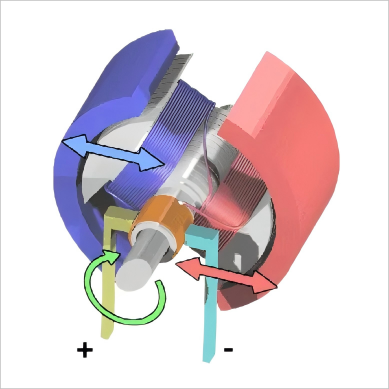

- Structure of a permanent magnet brushed DC motor

A magnetic DC motor mainly consists of a housing, stator, rotor, mechanical commutator, shaft, front and rear end covers, and bearings. The stator is constructed by embedding or bonding permanent magnet poles within the inner circle of the housing.

a. The housing is the component that supports the entire weight of the motor, and the permanent magnet poles are embedded or attached to the inner circular wall of the housing, forming the stator of the motor. The housing is also the magnetic conductor of the magnetic circuit of the permanent magnet poles in the stator. The housing of W-class micro permanent magnet DC brushed motors is mostly made of low carbon steel, while the housing and front and rear end covers of KW-class permanent magnet DC brushed motors can be cast from cast iron or welded from low carbon steel sheets.

b. To reduce additional losses, the rotor core of a permanent magnet DC brushed motor is made of laminated silicon steel sheets of 0.35mm to 1.0mm, with rotor slots punched out on the core. Windings are embedded in the rotor slots and connected to a mechanical commutator. The mechanical commutator continuously and regularly changes the direction of the current in the rotor windings, thereby changing the magnetism of the winding poles and causing them to interact with the stator permanent magnets, thus rotating the rotor.

Post time: Jan-12-2026