A miniature geared motor is a small, lightweight electric motor. A small gearbox is installed in front of the output shaft of an AC motor to reduce speed and increase torque, thus meeting the working requirements of various products and equipment. For precise drive applications, the selection of a miniature motor should consider the following points:

3. Power = Torque ÷ 9550 × Power Input RPM ÷ Speed Ratio ÷ Utilization Factor

For example, a 0.75W micro motor with an input speed of 10,000 rpm can generate 9550 × 0.5 ÷ (10000 ÷ 15) = 10.7 Nm.

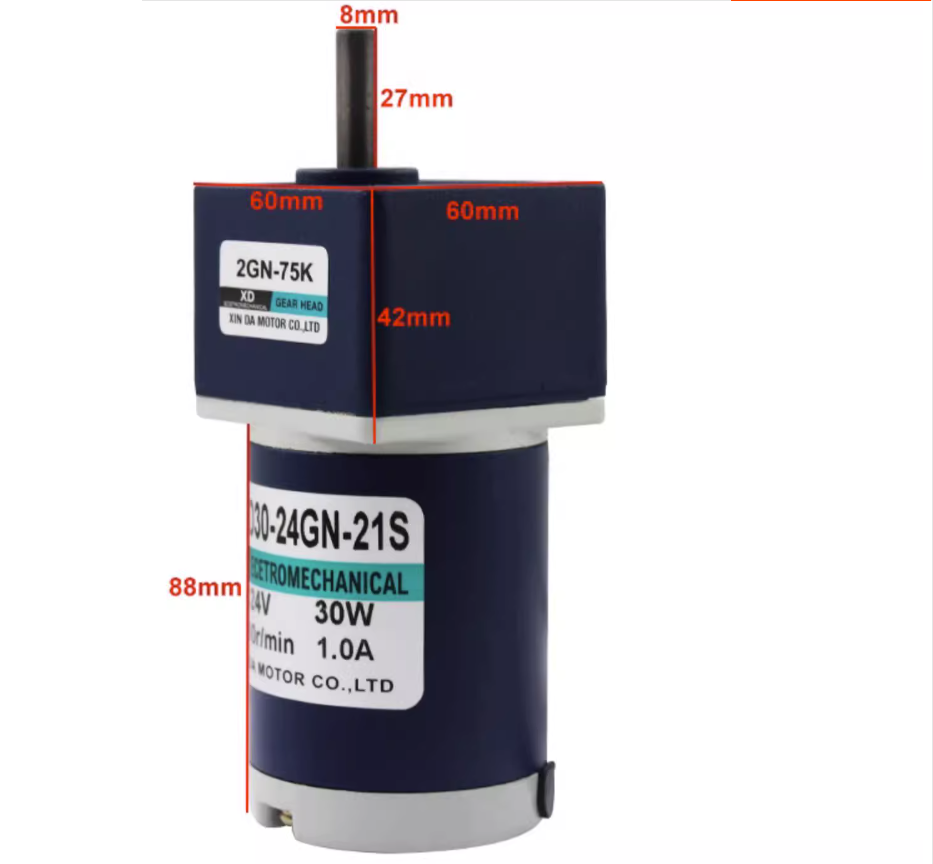

4. The selection of a miniature geared motor should match the motor mounting flange, because motors are classified according to their mounting flanges, and gearboxes are also modeled according to their mounting flanges.

5. Different application scenarios have different requirements for micro motors. For example, power tools require large torque and high speed, while electronic devices require small size and low energy consumption.

6. Determine the rated voltage and output speed, and calculate the required reduction ratio based on the output speed in order to select a suitable gearbox. Selecting the appropriate power is a basic factor for normal operation and an essential component for maximizing its performance.

Select the appropriate motor based on the load requirements of the equipment, including the required torque and power.

In the formula: P — power, kilowatts (kW); n — rated speed of the motor, revolutions per minute (r/min); T — torque, Newton-meters (N·m), 9550 is considered a constant.

Torque calculation plays a significant role in the lifespan of a speed reducer, so it is crucial to ensure that the maximum torque value of the acceleration does not exceed the maximum load torque of the speed reducer.

Post time: Jan-28-2026