- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

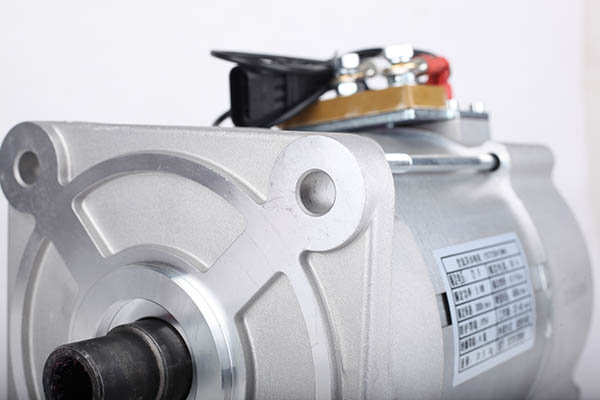

Electric forklift motor AC asynchronous motor walking motor lifting motor 5kw motor

| Origin | Zibo City, China | Insulation | H | Protection Level | IP56 |

| Customize | acceptable | Efficiency | Ie 3 | Brand | Xinda Motor |

| Motor Type | Three-phase asynchronous motor | Model No. | XQY5-72-H9-B | Rated Power | 5(kW) |

| Rated Vol. | 48/60V/72V(V) | Rated Speed | 3000(rpm) | Application | passenger cars, trucks, vans, forklifts |

Product Parameter

| Warranty | 3months-1year |

| Place of Origin | Shandong, China |

| Brand Name | Xinda Motor |

| Model Number | XQY5-72-H9-B |

| Type | Asynchronous Motor |

| Phase | Three-phase |

| Protect Feature | Drip-proof |

| AC Voltage | 72V |

| Efficiency | Ie 3 |

| rated power | 5KW |

| Peak power | 12.5KW |

| Rated voltage | 72V |

| Rated torque (N.m) | 15.9 |

| Rated speed | 3000r/min |

| Peak speed | 6000r/min |

| Working system | S2:60 |

| Insulation class | H |

| Protection level | IP56 |

| Supply Ability | 40000 Set/Sets per Month |

| Packaging Details | Carton or wooden case |

| Port | Qingdao or as required |

The advantages of our company's AC motor

1. Balanced and reliable. It is connected with the vehicle drive axle of the involute spline shaft to provide a reliable safety guarantee for the vehicle.

2. Climbing ability. High starting torque, larger speed tunable range and higher peak speed, higher overload capacity, which will provide electric vehicles with high power to meet the needs of climbing.

3. Long drive range on a single charge. Higher motor efficiency, providing effectiveness.

4. Anti-skid prevention ability. When the Golf is on a slope, the AC motor keeps it from slipping.

5. The ability to adapt to different road conditions, enabling regenerative braking.

6. Durable and easy to maintain.

Product Photo

Applicable vehicle: Forklift

| DPD ACAM(AC ASYNCHRONOUS) Motor Series Specification Sheet | ||||||||||||

| Rated Power (KW) | 3 | 4 | 5 | 6 | 7.5 | 10 | 13 | 15 | 15 | 20 | 25 | 30 |

| Battery Voltage (VDC) | 48/60/72 | 48/60/72 | 48/60/72 | 72 | 72/96 | 72/96 | 72/96 | 108 | 96/144 | 96/144 | 312 | 96/144 |

| Peak Power (KW) | 7.5 | 10 | 12.5 | 15 | 18.7 | 25 | 32.5 | 31 | 28 | 40 | 45 | 60 |

| Rated Current (A) | 78/59/52 | 98/78/65 | 123/98/82 | 98 | 118/89 | 154/116 | 200/150 | 154 | 174/116 | 231/154 | 92 | 347/231 |

| Rated Torque (N.M) | 19/19.5 | 25.5/12.74 | 31.8/26.5/15.9 | 15.9 | 23.9 | 53 | 41.4 | 65.1 | 47.8/39.8 | 63.7 | 57.4 | 95.5 |

| Peak Torque (N.M) | 66.5/38 | 89.3/51 | 95.4/78.5/71.5 | 63.7 | 95.2 | 159 | 144.9 | 106.3 | 130/150 | 223 | 160 | 334.2 |

| Rated Speed (RPM) | 1500/3000 | 1500/3000 | 1500/1800/3000 | 3600 | 3000 | 1800 | 3000 | 2200 | 3000/3600 | 3000 | 4160 | 3000 |

| Peak Speed (RPM) | 4500/6000 | 4500/6000 | 4500/6000 | 6000 | 5400 | 6000 | 7500 | 6000 | 6800 | 6000 | ||

| Working System | S2:60min | S2:60min | S2:60min | S2:60min | S2:60min | S2:60min | S2:60min | S9 | S9 | S9 | S9 | S9 |

| Insulation Level | H | H | H | H | H | H | H | H | H | H | H | H |

| Cooling Method | natural cooling | natural cooling | natural cooling | natural cooling | natural cooling | natural cooling | natural cooling | natural cooling | natural cooling | natural cooling | natural cooling | water cooling |

| Efficiency (100% LOAD) | 85 | 85 | 85 | 85 | 88 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| Protection Level | IP54 | IP54 | IP54 | IP54 | IP54 | IP54 | IP67 | IP68 | IP69 | IP70 | IP71 | IP72 |

| Application | low-speed passenger/logistic vehicle | high-speed passenger/logistic/SUV | minibus logistic vehicle |

|||||||||

Real copper core is the key for reliability

Instructions for use

1. The user must follow the requirements of this instruction.

2. The motor should be stored in a ventilated, dry and clean environment. If the storage time is too long (six months) , it is necessary to check whether the bearing grease is dry. The normal insulation resistance value of the test winding should not be less than 5MΩ , otherwise it must be dried in an oven at 80 ± 10 ℃ .

3. For the bearingless motor at the shaft extension end, it should be adjusted after installation to check whether the rotor is flexible and there is no rubbing phenomenon.

4. Check whether the motor connection cable is correct and reliable.

5. Check whether the surface of the commutator is oily, and the brushes should slide freely in the brush box.

6. The series motor should not be powered on and run under no-load. If the user must run at no-load, the voltage should be controlled within 15% of the rated voltage.

7. There should be no corrosive gas in the cooling air.

Use environment

1. The altitude does not exceed 1200 meters.

2. The ambient temperature is between -25 ℃ and 40 ℃ .

3. When the relative humidity reaches 100% , condensation will form on the surface of the motor.

4. The motor is divided into fully enclosed type and open type. The fully enclosed can prevent the entry of foreign matter, dust and water, and the open type can be more convenient to maintain the commutator and replace the brush.

5. The maximum allowable current of the motor for short-time overload is 3 times the rated value. At this time, the overload torque is 4.5 times the rated torque, and the time should not exceed 1 minute.

Applicable in wide range

Xinda motor products are widely used in building automation, security monitoring, laser equipment, textile equipment, machine tool equipment, medical equipment, logistics automation and new energy and other fields.

Applicable vehicles

Xinda Motor is suitable for various types of vehicles: sightseeing cars, buses, police cars, four-wheeled cars, golf carts, three-wheeled motorcycles, forklifts, and environmental patrol cars.

Common faults and solutions of motors

(a) The motor cannot be started

1. The power supply phase is missing or the power supply voltage is too low. Solution: Check whether there is any disconnection in the stator winding, and then check the power supply voltage.

2. Broken or desoldered rotor. The motor can be started with no load, but cannot be started with a negative load. Solution: Check the rotor for defects such as broken bars or cracks with a broken rotor bar tester.

3. The motor is overloaded or the transmission is stuck. Solution: Choose a motor with a larger capacity to eliminate the failure of the mechanical rotating mechanism.

(b) The three-phase current of the motor is unbalanced

1. The three-phase power supply voltage is unbalanced. Solution: Measure the supply voltage with a voltmeter.

2. Some coils in the stator winding are short-circuited. Solution: Measure the three-phase current with an ammeter or disassemble the motor to check the overheated coil manually.

(c) Overheating of motor bearings

1. The bearing is damaged. Solution: Replace the bearings with new ones.

2. The bearing is too tight or too loose with the shaft or end cover. Solution: Repair the shaft or end cap to fit the shaft to the bearing.

3. Too much grease, too little or too dirty, there are sand and dust foreign objects. Solution: Clean the bearings and fill with clean grease.

4. The motor installation is not concentric. Solution: Adjust the coaxial condition of the motor installation.

Packaging Details

Regular motors use carton packaging, and high power motors use wooden box packaging