PX series miniature current geared motor

Overview

J-SZ(ZYT)-PX series miniature DC geared motors are respectively composed of SZ(ZYT) series DC motors and PX type ordinary precision planetary reducers, and equipped with power supply, which can realize stepless speed regulation. Wide adjustment range, small size, light weight, high efficiency, compact structure, large output torque, widely used in drives that require low speed, high torque, and stepless speed regulation. Infinitely variable speed.

PX series planetary gear reducer can be directly connected to AC motors, stepper motors and other motors.

PX series can also be directly connected to worm gear reducer and cycloidal pinwheel reducer to form reducers with different speed ratios or large speed ratios.

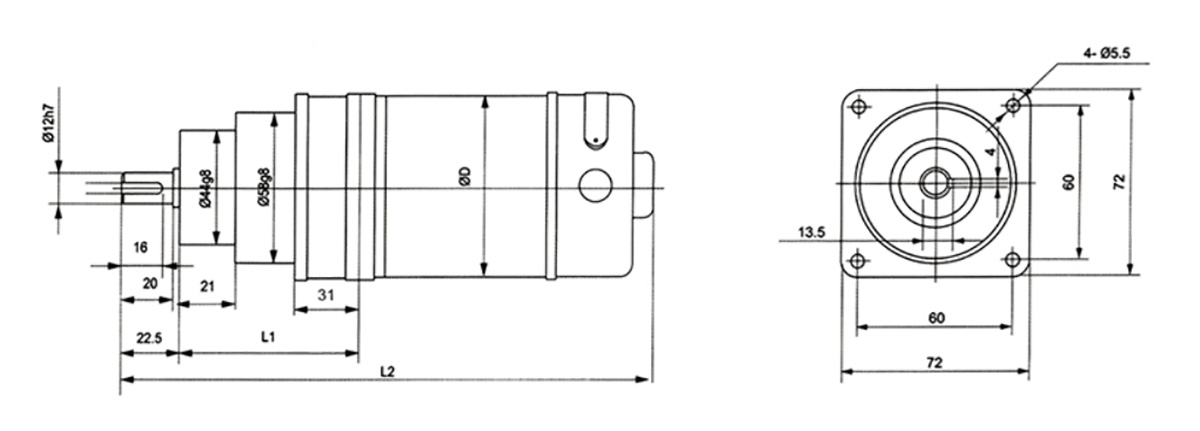

Reducer Model Instruction

Motor Model

A1- installation form: A1 is foot installation, A3 is flange installation, B5 is round flange installation

64 -Reduction ratio: 1:64

PX - Ordinary Precision Planetary Reducer

54 - Motor performance parameter code

SZ(ZYT ) - DC Servo Motor (Permanent Magnet DC Motor)

90 - Motor base number: Indicates outer diameter of 90mm

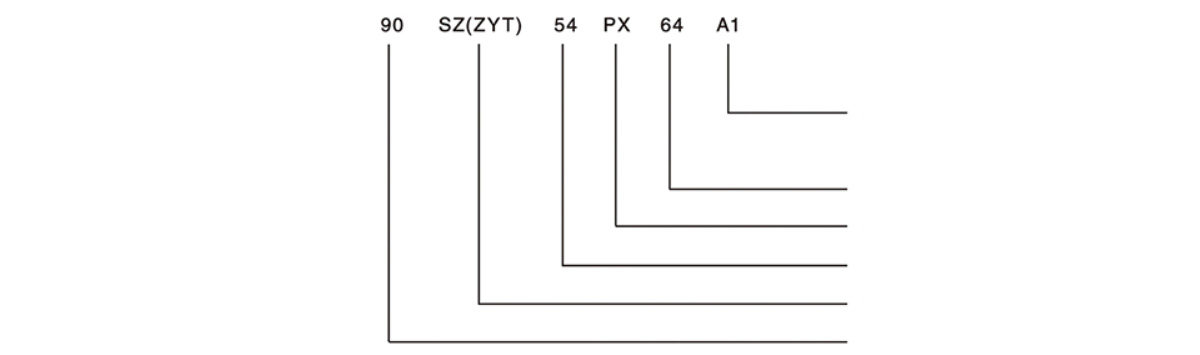

Reducer Model

A1- installation form: A1 is foot installation, A3 is flange installation, B5 is round flange installation

16 - Reduction ratio: 1:64

PX - Ordinary Precision Planetary Reducer

110 - Motor base number: Indicates outer diameter of 90mm

The technical data of electric motor

| Speed(r/min) | Torque(mN.m) | Model | Power | Rated Speed (r/min) | Install | Rated Voltage | Reduce Ratio | Remarks | |

| 750 | 260 | 55ZYT | 29 | 3000 | A3 | 24V:55ZYT51 27V:55ZYT52 48V:55ZYT53 110V:55ZYT54 | 4 | ||

| 187.5 | 740 | 16 | |||||||

| 47 | 21200 | 64 | |||||||

| 12 | 5900 | 256 | |||||||

| 500 | 390 | 6 | |||||||

| 83 | 1660 | 36 | |||||||

| 14 | 7180 | 216 | |||||||

| 750 | 450 | 70ZYT01 | 50 | 30000 | 24 | 4 | |||

| 70ZYT02 | 27 | ||||||||

| 70ZYT03 | 48 | ||||||||

| 70ZYT04 | 110 | ||||||||

| 1500 | 380 | 70ZYT05 | 85 | 6000 | 24 | 4 | |||

| 70ZYT06 | 27 | ||||||||

| 70ZYT07 | 48 | ||||||||

| 70ZYT08 | 110 | ||||||||

| 750 | 630 | 70ZYT51 | 70 | 3000 | 24 | 4 | |||

| 70ZYT52 | 27 | ||||||||

| 70ZYT53 | 48 | ||||||||

| 70ZYT54 | 110 | ||||||||

| 1500 | 540 | 70ZYT55 | 120 | 6000 | 24 | 4 | |||

| 70ZYT56 | 27 | ||||||||

| 70ZYT57 | 48 | ||||||||

| 70ZYT58 | 110 | ||||||||

| 187.5 | 1270 | 70ZYT01 | 50 | 3000 | 24 | 16 | |||

| 70ZYT02 | 27 | ||||||||

| 70ZYT03 | 48 | ||||||||

| 70ZYT04 | 110 | ||||||||

| 187.5 | 1780 | 70ZYT51 | 70 | 3000 | 24 | 16 | |||

| 70ZYT52 | 27 | ||||||||

| 70ZYT53 | 48 | ||||||||

| 70ZYT54 | 110 | ||||||||

| 47 | 3670 | 70ZYT01 | 50 | 3000 | 24 | 64 | |||

| 70ZYT02 | 27 | ||||||||

| 70ZYT03 | 48 | ||||||||

| 70ZYT04 | 110 | ||||||||

| 750 | 360 | 70SZ01 | 40 | 3000 | 24 | 24 | 4 | ||

| 70SZ02 | 27 | 27 | |||||||

| 70SZ03 | 48 | 48 | |||||||

| 70SZ04 | 110 | 110 | |||||||

PS series general speed ratio

Level 1: 4 , 6

Secondary: 16 , 24 , 36

Level 3: 64 , 96 , 144 , 216

Level 4: 256\384\576\864\1296

90PX series non-standard speed ratio

Level 1: 3

Level 2: 9 , 12 , 18

Level 3: 27 , 48 , 54 , 72 , 108

Level 4: 81 , 162 , 192 , 288 , 324 , 432 , 648

110PX series non-standard speed ratio

Level 1: 5

Level 2: 20 , 25 , 30

Level 3: 80 , 100 , 120 , 125 , 150 , 180

Level 4: 320 , 400 , 480 , 500 , 600 , 625 , 720 , 750 , 900 , 1080

Non-standard reducers such as special speed ratio, speed, installation size, etc. can be designed

Selection example

The user can correctly select the power and model of the reducer according to the actual working system and the nature of the load by referring to the following contents.

1. According to the load torque and the output speed of the reducer, the required power can be calculated by the following formula: P=T n/kh

In the formula: P- output power W T - load torque Nm, select n- output speed r/min according to the technical data sheet

K- load constant 9560 η - transmission efficiency, selected from the following table

Transmission Ratio

| Transmission ratio(i) | 4(6) | 16(36) | 64(216) | 256(1296) |

| η | 0.76 | 0.72 | 0.68 | 0.65 |

2. The motor governor can be selected to realize the stepless speed change of the reducer from O to the rated speed.

3. According to the actual working system and load nature, the service coefficient can be selected with reference to the service coefficient table. After calculation, the required power of the reducer can be determined, and according to the required output speed, the reducer model can be selected by referring to the technical data table.

Working Index Sheet

| Daily Work Time | Load Level | |||

| Average steady | Medium vibrant | Heavily impact | ||

| 12 | 1 | 1.25 | 1.75 | |

| 24 | 1.25 | 1.50 | 2 | |

For example: if the load is even and stable, the required motor rated power is 40W, the rated voltage is 110V, the output speed ratio is 4, and the working time per day is 12h, then 40W is selected . If the nature of the load is moderate vibration:

Then: a. Refer to the service coefficient table to select the service series as 1.25 . Required power W=40W*1.25=50W

b. Check the technical data sheet for optional J70SZ54P*4

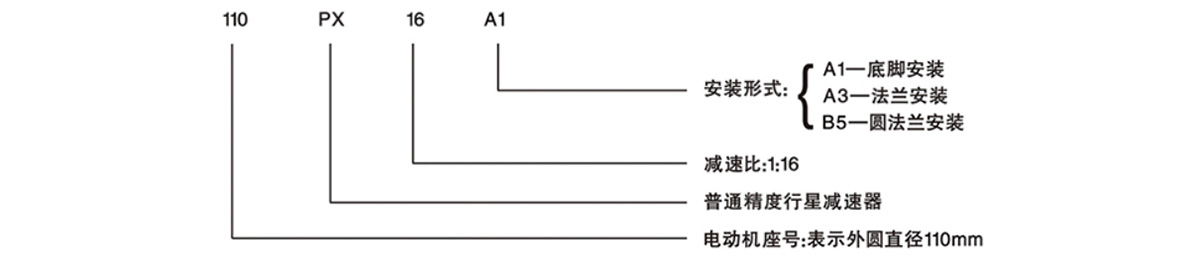

70PX front flange

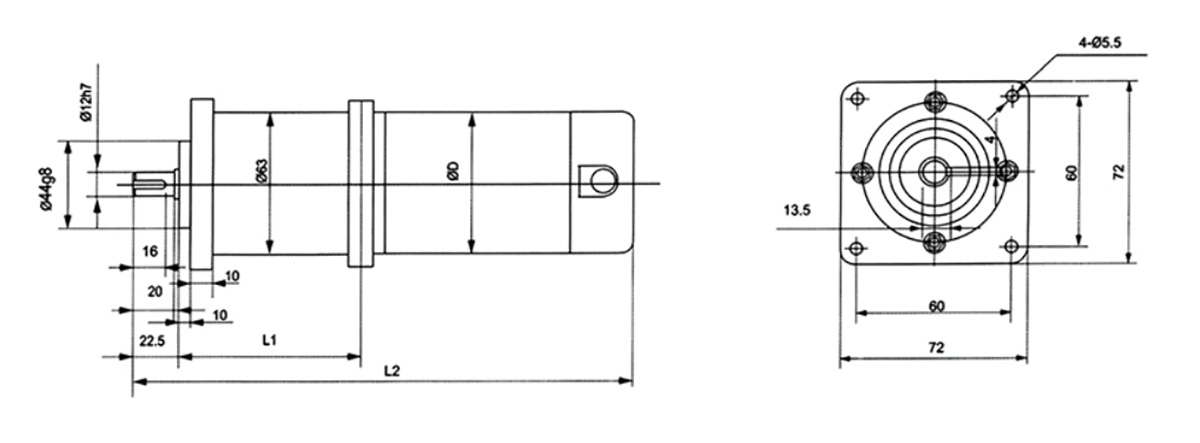

70PX rear flange